20 November, 2020Battery production will be one of the fastest growing industrial activities in the years to come. Due diligence and opportunities for organizing along the complex supply chain were discussed at a webinar bringing together unions, experts as well as industrial directors.

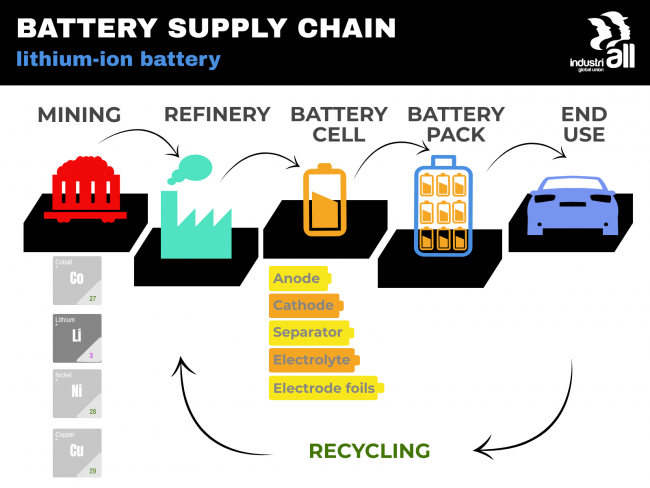

Battery power is rapidly becoming essential to our daily lives as society becomes increasingly digitally connected with electrical and electronics devices with electric vehicles being the main driver. The battery supply chain is complex and ranges from precarious and extremely dangerous artisanal mining to well organized auto manufacturing.

IndustriALL represents workers along the entire battery supply chain, with the exception of the business that is taking place in China, and is involved in the due diligence processes to secure workers’ rights and organize workers.

The demand for critical raw materials for the low carbon energy transition batteries, cobalt, lithium, copper and nickel, etc. will likely follow the same upstream demand side (mining) narrative of human rights’ violations and unacceptable environmental consequences: child labour, destruction of the living environment of indigenous peoples, ecological destruction, water shortage etc.

Andy Leyland from Benchmark Minerals discussed the risk that the quest for cheaper electric vehicles and the batteries used will lead to a race to the bottom, where the workers at the bottom of the supply chain will be the worst off in terms of wages and working conditions.

Moreover, he illustrated that the costs for batteries – against all market expectations – are likely to go up as the demand for the required raw materials will grow faster than new mining capacities can be created.

IndustriALL assistant general secretary Atle Høie said that drawing from the experiences from the work in the garment supply chain, working with a cross-sectorial along the battery supply chain opens the opportunity for a comprehensive and sustainable supply chain strategy.

“This will improve the effectiveness of due diligence processes, the enforcement of workers’ and human rights and the promotion of decent working conditions. The further down you get along the supply chain, there are more unorganized workers and substandard wages and working conditions. We need to examine our leverage in the higher end of the supply chain in order to put pressure on the companies operating in the lower parts of the supply chain.”

Speaking at the webinar, Aimee Boulanger, executive director of IRMA, the initiative for responsible mining, welcomed the membership of German automaker BMW earlier this year. She mentioned that other auto makers (the day after the workshop Daimler joined IRMA as a new member) could potentially follow BMW’s lead and join IRMA, underscoring the importance of supply chain due diligence in the global battery supply chain.

Glen Mpufane, IndustriALL mining director, described the importance of the sector for the low carbon energy transition and how the emergence of supply chain due diligence requirements in procurement could be a powerful tool to improve the performance of the sector in ESG (environment, social and governance), with a particular emphasis on workers’ rights.

Kan Matsuzaki, director ICT, electrical and electronics, explained that 80 per cent of the electric vehicle battery output is manufactured by six suppliers from China, Japan, and Korea.

“These major manufacturers are now investing outside of China, where IndustriALL’s unions are active, like in Germany, UK, USA and Eastern Europe. It is important to set up concrete organizing strategies for this rapidly expanding industry.”

Diana Junquera, energy industry director, mentioned that all the large electricity multinationals are investing in the Battery Energy Storage System (BESS), as a way to accumulate and use unconsumed electricity from the grid. Oil companies are installing electric recharging points for electrical vehicles as well.

“IndustriALL represent workers in these companies and even has global framework agreements with some of them. This is why we can reach all parts of the supply chain to ensure decent working conditions for the workers.”

Armelle Seby, gender coordinator, said:

“It is important to develop a gender responsive approach addressing existing gender-based inequalities and violence along the battery supply chain. Integrating such an approach in due diligence processes limits a negative impact on women’s rights, and also brings systematic changes to discriminatory power structures.”

Georg Leutert, automotive industry director, pointed to the fact that automotive manufacturers had to shoulder an important part of the responsibility regarding socially responsible business conduct in battery supply chains. He also mentioned that auto unions are hoping for the creation of a maximum of jobs to compensate for the losses in traditional engine and transmissions plants.

“There is still a lot of movement in the make or buy decisions regarding batteries. And this is not only about insourcing the cell manufacturing but some companies are even becoming active in purchasing the raw materials themselves.”

Tom Grinter, chemical sector director outlined the main contribution by chemical workers to this supply chain. With materials, technologies, and research, chemical companies are heavily investing into this growing business. Three companies were highlighted that are both important players in the industry, and strongly organised by IndustriALL affiliates around the world, BASF, Solvay, and Umicore.

IndustriALL has applied for funding for a project starting in January 2021 on the battery supply chain across the industrial sectors. In a pilot project IndustriALL intends to collaborate with companies, NGOs and other associations to find out how such an approach can help to genuinely improve the situation workers along the entire battery supply chain.

“We have to use all resources to ensure that workers’ rights are upheld in the entire supply chain and pressure for more transparency,”

said Atle Høie.